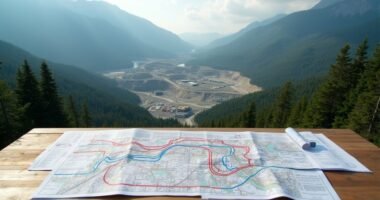

The Mount Polley tailings dam breach serves as a cautionary tale for the mining industry. Design flaws, like underestimating the vulnerability of clay-rich sediments, and poor geological assessments released chaos. Think of it as building a sandcastle on a tidal shore—it looks great until the waves come crashing. These failures happen every decade due to similar oversights and outdated safety standards. For a deeper exploration into how these issues persist, just stick around for more insights.

Quick Overview

- Undetected weaknesses in dam design, such as overlooked sediment layers, lead to catastrophic failures like the Mount Polley breach.

- Design flaws, including inadequate geological investigations and reliance on risky construction methods, compromise dam stability and safety.

- Environmental restoration challenges post-breach highlight the long-term impacts of mining waste on ecosystems and the need for better planning.

- Future mining operations must prioritize engineering controls, real-time monitoring, and regular equipment maintenance to prevent similar disasters.

- Promoting a safety culture through regulatory compliance, environmental assessments, and open communication is essential to mitigate mining risks.

Understanding the Undetected Weaknesses of Mount Polley

While geologists and engineers often approach dam design with a sense of confidence, the Mount Polley incident serves as a cautionary tale about the undetected weaknesses lurking beneath the surface.

An essential layer of glaciolacustrine sediment, composed of clay and silt, was overlooked during initial investigations. This sneaky layer, much like a hidden trapdoor, became too weak under pressure from the dam’s growing weight. The failure to recognize its complexity and behavior led to disastrous consequences. It’s a classic case of “what you don’t know can hurt you,” reminding us that even the most solid-looking foundations can harbor hidden vulnerabilities. This failure reflects the importance of considering the complete lifecycle of mining operations, from initial material extraction through ongoing maintenance to eventual closure. The investigation found that adequate studies on the perimeter embankment foundation were not conducted, which contributed to the breach.

What Design Flaws Caused the Mount Polley Disaster?

What could possibly go wrong when a dam designed to hold massive amounts of water and tailings is constructed with questionable assumptions? The Mount Polley disaster highlights several design flaws.

Engineers underestimated the clay-rich glacial sediments beneath the dam, failing to recognize their vulnerability under stress. Slope steepness was increased to save on rockfill, compromising stability. Design inadequacies led to a weak foundation that ultimately contributed to the dam’s sudden failure. Utilizing “upstream” construction methods only exacerbated the risks associated with these design flaws.

Imagine building a tower on a wobbly base – not a great idea! Inadequate geological investigations and modifications during construction led to a mismatch between the design and reality. Site rehabilitation efforts after the breach demonstrated the enormous challenges of restoring ecosystems damaged by mining waste.

Like trying to fit a square peg in a round hole, these oversights set the stage for catastrophe.

Key Takeaways for Future Mining Safety

The Mount Polley disaster serves as a stark reminder that mining safety isn’t just a box to check off; it’s a complex puzzle that requires careful assembly.

Future mining safety hinges on engineering controls, like ventilation systems that keep air clean and hazards at bay. Real-time monitoring and data analytics are essential for spotting trouble before it escalates. Regular maintenance of heavy equipment can also prevent mechanical breakdowns that contribute to accidents. Additionally, operators must ensure compliance with revised PEL standards to significantly reduce silica dust exposure among miners.

Thorough training guarantees workers know their gear and escape routes. Regulatory compliance, particularly with updated silica standards, protects both workers and the environment. Comprehensive environmental assessments must be conducted before project implementation to identify potential hazards and mitigate risks.

Finally, an organizational culture that prioritizes safety and open communication fosters accountability, turning hazards into manageable puzzles instead of ticking time bombs.